Expert Technicians

Original Parts

Fast Turn-Arounds

Maintenance Plans

Comprehensive Repair and Calibration Services for the Burleigh WA-7100 Wavelength Meter at Wyoming Electronics Inc.

At Wyoming Electronics Inc., we specialize in expert repair services for the Burleigh WA-7100 Wavelength Meter, ensuring your critical measurement equipment functions seamlessly and accurately. Our skilled technicians are equipped with advanced diagnostic tools and extensive expertise to address a broad spectrum of technical issues efficiently.

Full Service Repair Solutions for the Burleigh WA-7100 Wavelength Meter:

The Burleigh WA-7100 is a precision instrument designed for detailed optical analysis across a broad wavelength range. However, even the most reliable instruments can encounter operational challenges. Our services are designed to address and resolve these issues promptly and effectively.

Key Repair Services Include:

- Operational and Startup Issues:

- Startup Failures: We address problems like the device being stuck on initializing step 8/8 or not booting at all, ensuring a smooth startup.

- Display Problems: We repair units that have no display output, restoring full operational visibility.

- Optical Measurement Challenges:

- Optical Signal Detection Failures: We correct failures in detecting optical signals, essential for the device’s primary functionality.

- Power Button Malfunctions: We provide quick repairs or replacements for malfunctioning or stuck power buttons.

- Calibration and Alignment:

- Wavelength Calibration Errors: We handle both internal and external wavelength calibration failures to ensure the analyzer meets all specified accuracy standards.

- Optical Alignment Problems: Our services include rectifying internal optical alignment issues that could significantly impact accuracy.

- Monochromator Errors: We troubleshoot and resolve issues with the monochromator, crucial for accurate wavelength analysis.

- Low Optical Power Readings: Adjustments or repairs are made to enhance the accuracy of optical power readings.

Why Choose Wyoming Electronics Inc.?

- Expert Technicians: Our team is highly experienced with the Burleigh WA-7100, ensuring knowledgeable and precise service.

- Advanced Diagnostic and Repair Tools: We use the latest technology in diagnostics and repair to swiftly identify and correct issues, reducing downtime.

- Transparent Pricing: Our maximum service charge is $6500, but each client receives a detailed quote after a comprehensive evaluation.

- Quick Turnaround Time: We understand the importance of minimizing downtime in your operations and strive to complete repairs quickly and efficiently.

Schedule Your Burleigh WA-7100 Repair Today

If your Burleigh WA-7100 Wavelength Meter is experiencing operational issues, don’t hesitate to contact Wyoming Electronics Inc. today. Our prompt and reliable service ensures your equipment is quickly restored to optimal functionality, allowing you to continue delivering precise and reliable optical analyses. Trust us to maintain your equipment at the highest industry standards.

Steps to getting your Burleigh WA-7100 fixed:

1) Fill our RMA form here, and ship us your defective WA-7100

2) We will perform free evaluation and quote you with lead time

3) You will accept or decline the repair

4) We will repair and or return your WA-7100

To ensure that the Burleigh WA-7100 Wavelength Meter operates at its peak performance and meets the critical specifications outlined, we at Wyoming Electronics Inc. follow a detailed and methodical approach to fixing and calibrating the device. Here’s how we address each specific issue related to the given specifications:

1. Wavelength Range and Uncertainty

Range: 1270 nm to 1680 nm (178 THz to 236 THz) Uncertainty: (3?) (pm) ± 0.3

To ensure the wavelength range and uncertainty are maintained within specifications, our technicians start with a thorough check of the monochromator and the associated optical components that contribute to wavelength discrimination. Calibration involves using traceable wavelength standards to adjust the device’s settings until the measured uncertainty aligns with the specified ±0.3 pm. This process may include adjustments to the grating alignment and verification of the detector’s linearity across the stated range.

2. Minimum Resolvable Separation

Separation: 30 pm

Achieving a minimum resolvable separation of 30 pm requires precise alignment and calibration of the optical system, particularly focusing on the resolution capabilities of the monochromator. We utilize finely calibrated light sources with known peak separations to ensure the device can effectively resolve details to this level, adjusting optical alignments and detection thresholds as necessary.

3. Optical Power Uncertainty

Uncertainty: ± 0.5 dB (2?) within ± 30 nm from 1310 nm and 1550 nm

Calibrating optical power uncertainty, especially near critical wavelengths like 1310 nm and 1550 nm, involves using stable, calibrated light sources and power meters to benchmark and adjust the device’s readings. Any deviations observed are corrected through electronic and optical adjustments within the device to ensure adherence to the ±0.5 dB uncertainty standard.

4. Linearity (dB)

Linearity: ± 0.3

Linearity in dB is crucial for ensuring that the device accurately represents signal strength across its dynamic range. We calibrate this by measuring the response to a logarithmically varying signal and adjusting system parameters to minimize any non-linear responses. This process ensures that the device maintains a linearity of ±0.3 dB across its operational range.

5. Optical Input

Input: 9/125 µm fiber

To maintain optimal performance with a 9/125 µm fiber input, we regularly clean and inspect all fiber connectors and interfaces for any signs of wear or contamination. The alignment of the fiber input with the internal optics is also checked to prevent any coupling losses or misalignments that could affect performance.

6. Voltage and Frequency

Range: 90 to 260 VAC, 50/60 Hz

The device’s power supply is tested under various voltages within the specified range to ensure stable operation regardless of local power supply variations. This includes checking the power supply unit for voltage regulation, filtering capabilities, and overall stability to handle the specified frequency variations.

7. Instrument Interface

Interface: GPIB (IEEE-488.2), RS-232, floppy disk drive

Ensuring that all interfaces are functional includes testing each communication port for correct operation. The GPIB and RS-232 ports are tested with standard communication protocols to verify data transmission and reception. The floppy disk drive is tested for both read and write capabilities, ensuring data can be stored and retrieved without errors.

- Wavelength Range: 1270 nm to 1680 nm (178 THz to 236 THz)

- Wavelength Uncertainty: ± 0.3 pm (3?)

- Minimum Resolvable Separation: 30 pm

- Optical Power Uncertainty: ± 0.5 dB (2?) within ± 30 nm of 1310 nm and 1550 nm

- Linearity in dB: ± 0.3

- Optical Input: Optimized for 9/125 µm fiber

- Voltage and Frequency: 90 to 260 VAC, 50/60 Hz

- Instrument Interface: Equipped with GPIB (IEEE-488.2), RS-232, and a floppy disk drive for versatile connectivity and data management

Calibration Certificate included!

Get a Quote for Service

Call : 215-485-6313

sales@wyomingelectronics.net

Additional information

| Model | |

|---|---|

| MPN | |

| Brand | |

| Trademark |

Can’t find what you are looking for?

Spectrum Analyzers

Spectrum Analyzers Network Analyzers

Network Analyzers Signal Analyzers

Signal Analyzers Logic Analyzers

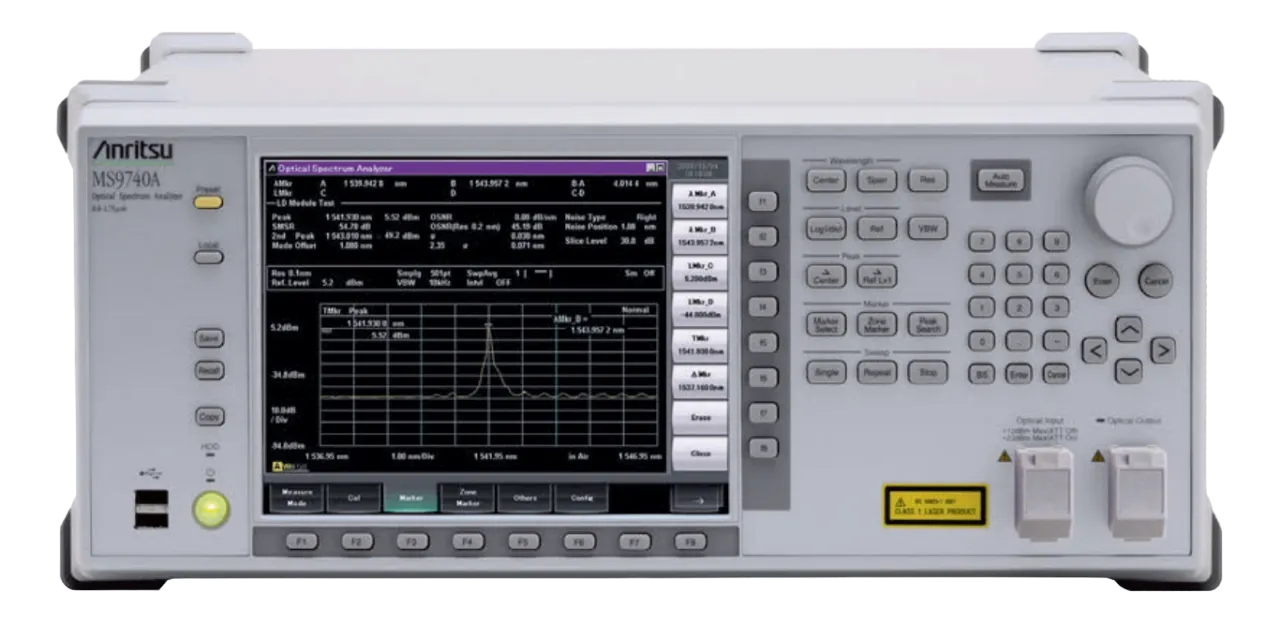

Logic Analyzers Optical Spectrum Analyzers

Optical Spectrum Analyzers Other Analyzers

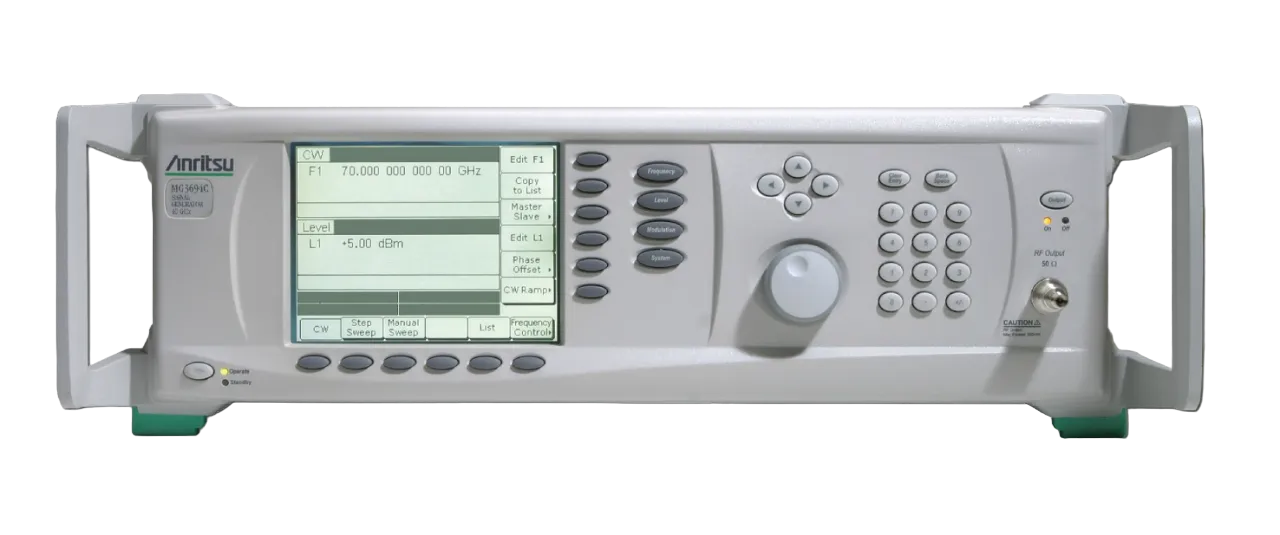

Other Analyzers Signal Generator

Signal Generator Function Generator

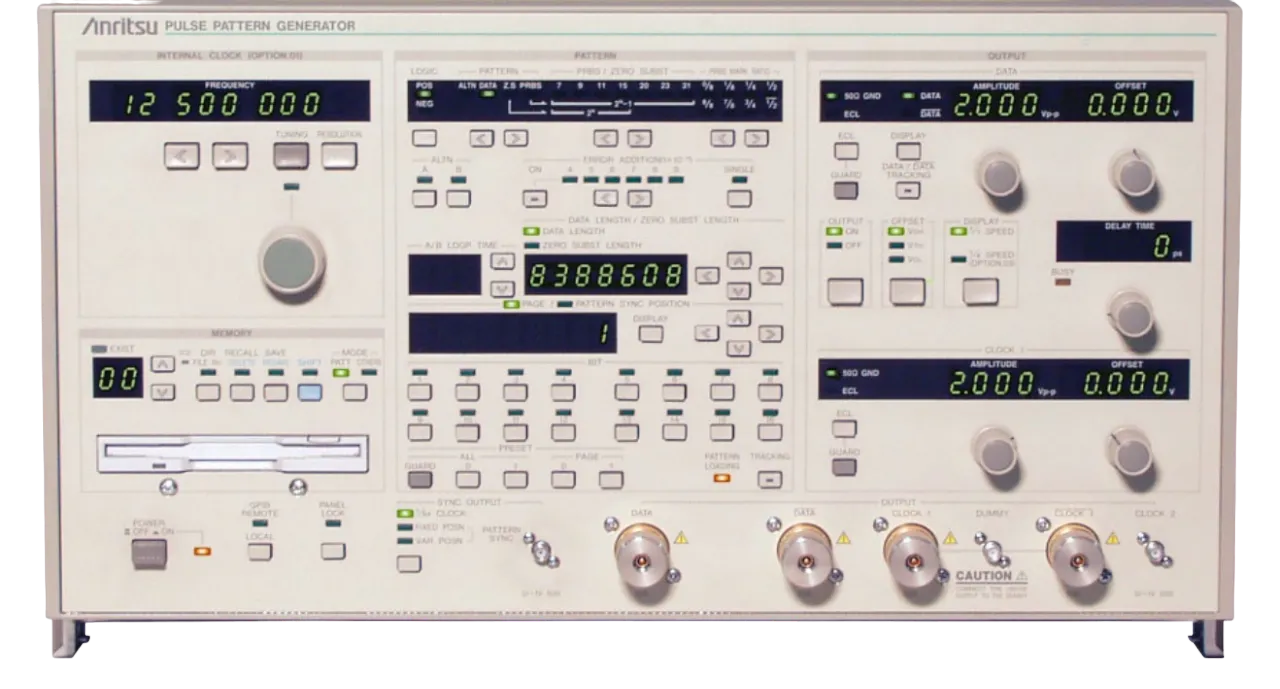

Function Generator Pulse / Pattern Generator

Pulse / Pattern Generator Waveform Generator

Waveform Generator Other Generators

Other Generators Digital Multimeter

Digital Multimeter Power Meter

Power Meter Frequency Counters

Frequency Counters Optical Power Meter

Optical Power Meter Wavelength Meter

Wavelength Meter Receiver

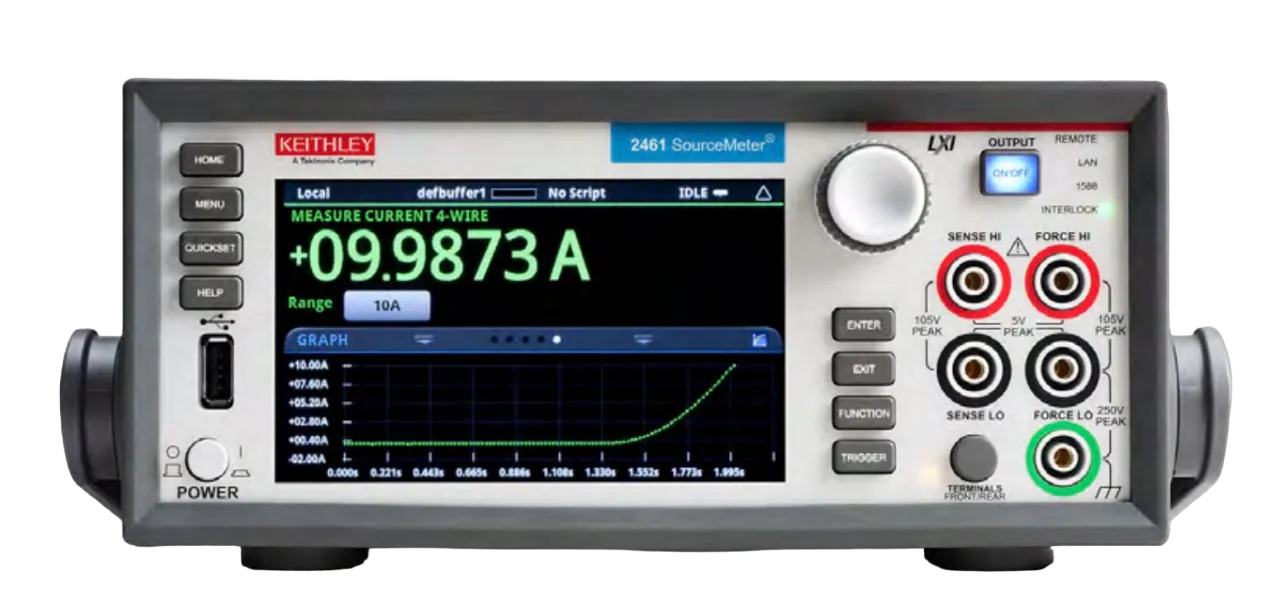

Receiver Current/Power Source Meter

Current/Power Source Meter Picoammeter

Picoammeter Other Meters

Other Meters Optical Fiber

Optical Fiber Fiber Cleaver

Fiber Cleaver Fusion Splicer

Fusion Splicer Fiber Recoater

Fiber Recoater Optical Attenuator

Optical Attenuator Optical Head

Optical Head OTDR (Optical Time-Domain Reflectometer)

OTDR (Optical Time-Domain Reflectometer) Other Optical Instruments

Other Optical Instruments Oscilloscopes

Oscilloscopes Curve Tracer

Curve Tracer EPROM Programer

EPROM Programer Recorder

Recorder Data Acquisition System

Data Acquisition System Data Logger

Data Logger Calibration Kit

Calibration Kit Test Set

Test Set Test Chamber / Ovens

Test Chamber / Ovens Calibrator

Calibrator Controller

Controller Mainframe

Mainframe Module

Module Interfaces(GPIB, Power)

Interfaces(GPIB, Power) Switch

Switch Matrix Cards

Matrix Cards Converter

Converter Multiplexer

Multiplexer Plug-in

Plug-in Simulator

Simulator LCR Meters

LCR Meters Filters

Filters Laser Drivers

Laser Drivers Error Detectors

Error Detectors Laser Source

Laser Source Probe

Probe Power Sensor

Power Sensor Amplifier

Amplifier Attenuator

Attenuator Optical Sensor

Optical Sensor Light/LED Source

Light/LED Source Broadband / Noise Source

Broadband / Noise Source Optical / Fiber Source

Optical / Fiber Source Power Supply

Power Supply Voltage Source

Voltage Source Polisher

Polisher Microscope

Microscope Adapter

Adapter Platforms/Mounts

Platforms/Mounts Bridges

Bridges Connectors & Accessories

Connectors & Accessories View All Products >

View All Products >