Expert Technicians

Original Parts

Fast Turn-Arounds

Maintenance Plans

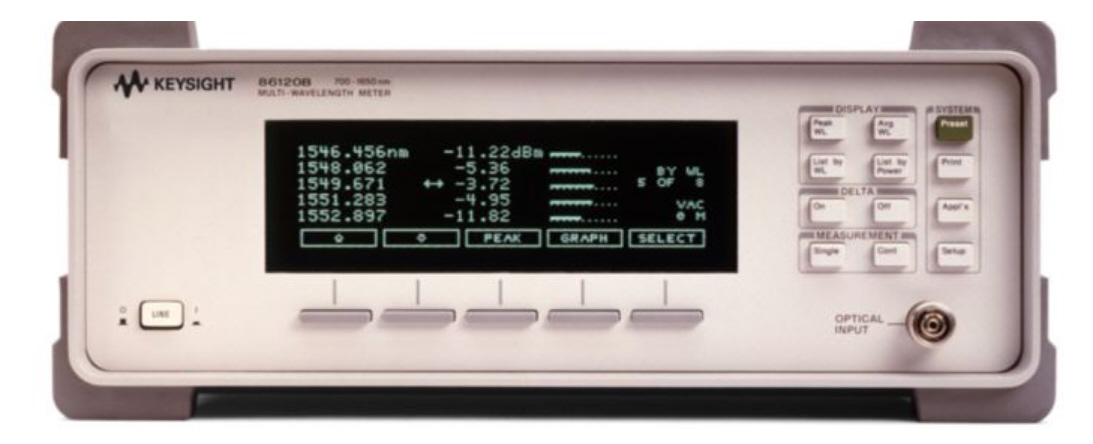

Comprehensive Repair and Maintenance Services for the Agilent / HP 86120C Optical Wavelength Meter at Wyoming Electronics Inc.

At Wyoming Electronics Inc., we specialize in delivering top-tier repair, maintenance, and calibration services for the Agilent / HP 86120C Optical Wavelength Meter. Utilizing only genuine Agilent / HP replacement parts and the latest technological tools, our highly skilled technicians ensure your precision instrument performs optimally, adhering to stringent industry standards.

Expert Solutions for Common and Complex Issues

The Agilent / HP 86120C is renowned for its accuracy and reliability in measuring wavelengths. However, several issues can compromise its performance. Our comprehensive service offerings are designed to address and resolve a wide range of problems:

1. Inaccurate Readings: Fluctuations or instabilities in the optical signal can lead to inaccurate measurements. Our technicians employ advanced diagnostic tools to analyze and stabilize the optical signal, ensuring your readings are precise and reliable.

2. Calibration Out of Tolerance: Calibration drift is common with continual use over time. We conduct detailed recalibration procedures, adjusting the wavelength meter to factory settings to guarantee measurement accuracy.

3. Temperature Drift: Sensitivity to temperature changes can affect the instrument’s performance. We assess and calibrate the temperature compensation mechanisms within your device, ensuring consistent performance across varying environmental conditions.

4. Signal Detector Issues: Problems such as noise or physical damage to the detector can significantly impair the meter’s accuracy. Our team is equipped to repair or replace faulty detectors, restoring functionality and measurement precision.

5. Compatibility Issues: Compatibility with various types of optical signals or devices is crucial for seamless operation. We evaluate and modify system configurations to enhance compatibility, ensuring your wavelength meter works effectively with all relevant technologies.

6. Instrument Failure: Complete failures may occur due to issues like a malfunctioning control board, a failing power supply, or other critical components. We provide thorough inspections and repairs, replacing defective parts to revive your instrument.

Calibration and Testing Services

To ensure that the Agilent / HP 86120C meets all operational specifications after repair and maintenance, we perform extensive calibration and testing. This includes:

- Wavelength Accuracy and Stability Testing: Utilizing certified light sources to verify the accuracy of wavelength measurements.

- Signal Integrity Checks: Ensuring the optical signal is captured and interpreted correctly by the wavelength meter.

- Environmental Robustness Testing: Assessing how the device performs under different environmental conditions to ensure reliability.

- Interface and Connectivity Tests: Verifying that all communication ports (GPIB, RS-232) are functioning correctly for data transfer and operation.

Why Choose Wyoming Electronics Inc.?

- Expertise: Our team has extensive experience and specialized training in handling and repairing the Agilent / HP 86120C, ensuring that all services are performed expertly.

- Quality: We use only OEM parts and follow rigorous procedures to ensure each repair or calibration meets high-quality standards.

- Reliability: We understand the importance of dependable equipment in your operations, so we strive to deliver fault-free repairs and maintenance that you can trust.

- Customer Satisfaction: Our detailed and customer-focused approach ensures that every repair or maintenance job is completed to your full satisfaction.

Steps to getting your 86120C fixed:

1) Fill our RMA form here, and ship us your defective 86120C

2) We will perform free evaluation and quote you with lead time

3) You will accept or decline the repair

4) We will repair and or return your 86120C

At Wyoming Electronics Inc., addressing the specific issues related to the Agilent / HP 86120C Optical Wavelength Meter involves a detailed and systematic approach to ensure that every aspect of the device meets or exceeds its design specifications. Here is how we address and rectify issues related to each of the specified metrics:

1. Range and Uncertainty

- Range: 1270 nm to 1680 nm (178 THz to 236 THz)

- Uncertainty: (3?) (pm) ± 0.3

Resolution Approach: To ensure the wavelength meter operates accurately within this range, our technicians calibrate the device using precision light sources that cover the entire wavelength spectrum. The calibration process includes adjusting the internal wavelength scale and verifying it against known standards to achieve the low uncertainty of ± 0.3 pm. This requires careful adjustment of the device’s optical components, including the monochromator and detector alignment, to ensure precise measurements.

2. Minimum Resolvable Separation

- Separation: 30 pm

Resolution Approach: Achieving a minimum resolvable separation of 30 pm necessitates fine-tuning the optical resolution capabilities of the wavelength meter. This involves calibrating the spectral resolution by adjusting the slit widths and potentially the focal lengths within the optical system. We use a series of narrowly spaced laser lines to ensure that the device can accurately resolve features at or below the 30 pm threshold.

3. Optical Power Uncertainty and Linearity

- Uncertainty (2?): ± 0.5 dB (at ± 30 nm from 1310 nm and 1550 nm)

- Linearity (dB): ± 0.3

Resolution Approach: Optical power measurement and its linearity are crucial for accurate device performance. To address this, we calibrate the power detection system using calibrated power meters and attenuators to adjust the device’s response to a known input. The linearity is tested across the dynamic range to ensure that the device maintains a linearity error within ±0.3 dB, adjusting internal electronic settings and algorithms as necessary.

4. Optical Input and Power Supply Specifications

- Optical Input: 9/125 µm fiber

- Voltage and Frequency: 90 to 260 VAC, 50/60 Hz

Resolution Approach: Ensuring that the optical input is clean and correctly aligned is fundamental. We inspect and clean all fiber connectors and interfaces, and align them meticulously to prevent loss or misalignment issues. The power supply unit is tested under various input voltages to confirm stable operation across the specified range. This ensures the device can reliably operate in different power conditions without affecting performance.

5. Instrument Interface

- Interface: GPIB (IEEE-488.2), RS-232, floppy disk drive

Resolution Approach: To ensure the interfaces function correctly, we perform comprehensive tests on each communication protocol. This includes verifying the GPIB and RS-232 ports for correct data transmission and command responses and checking the floppy disk drive for operational integrity. Any issues found are addressed by repairing or replacing faulty components or updating firmware to ensure compatibility and functionality.

86120C Specifications

- Range: 1270 nm to 1680 nm (178 THz to 236 THz)

- Uncertainty: (3?) (pm) ± 0.3

- Minimum resolvable separation(pm): 30

- Uncertainty (2?): ± 0.5 dB (at ± 30 nm from 1310 nm and 1550 nm)

- Linearity (dB): ± 0.3

- Optical input: 9/125 µm fiber

- Voltage and frequency: 90 to 260 VAC, 50/60 Hz

- Instrument interface: GPIB (IEEE-488.2), RS-232, floppy disk drive

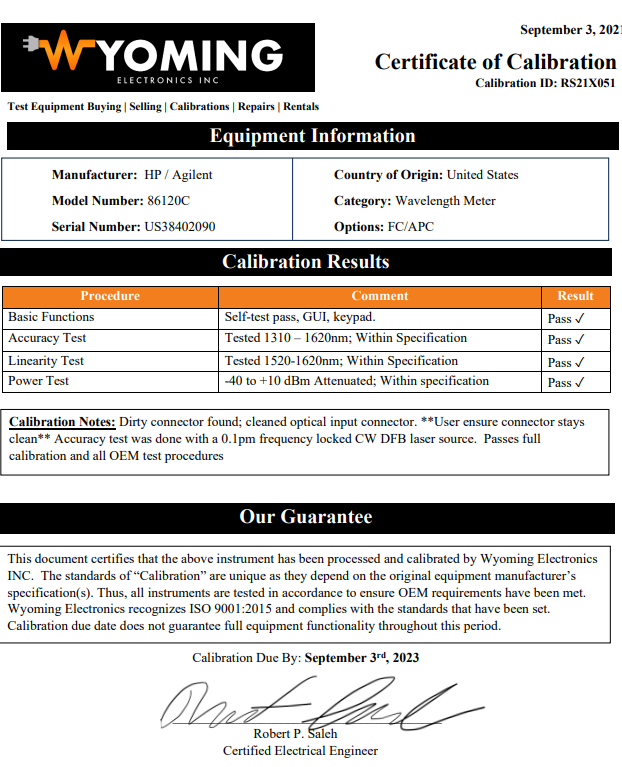

Calibration Certificate included!

Get a Quote for Service

Call : 215-485-6313

sales@wyomingelectronics.net

Additional information

| Brand | |

|---|---|

| MPN | |

| Wavelength Range | |

| Absolute WL Accuracy |

Can’t find what you are looking for?

Spectrum Analyzers

Spectrum Analyzers Network Analyzers

Network Analyzers Signal Analyzers

Signal Analyzers Logic Analyzers

Logic Analyzers Optical Spectrum Analyzers

Optical Spectrum Analyzers Other Analyzers

Other Analyzers Signal Generator

Signal Generator Function Generator

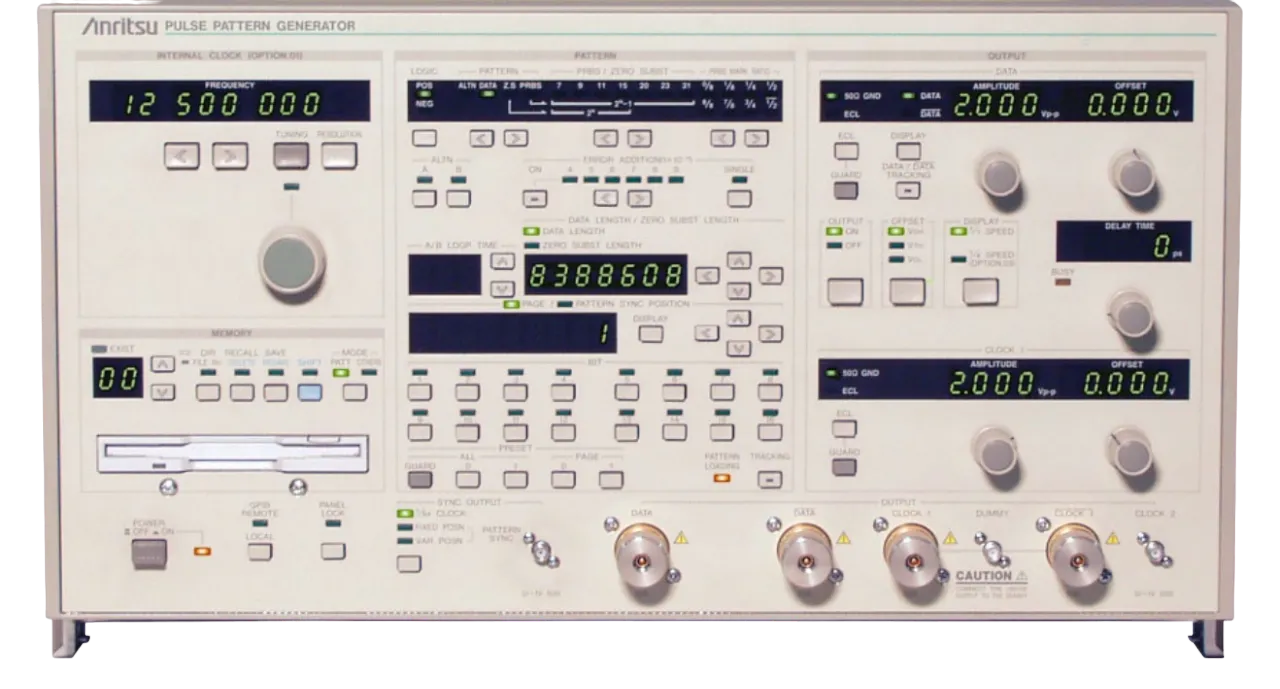

Function Generator Pulse / Pattern Generator

Pulse / Pattern Generator Waveform Generator

Waveform Generator Other Generators

Other Generators Digital Multimeter

Digital Multimeter Power Meter

Power Meter Frequency Counters

Frequency Counters Optical Power Meter

Optical Power Meter Wavelength Meter

Wavelength Meter Receiver

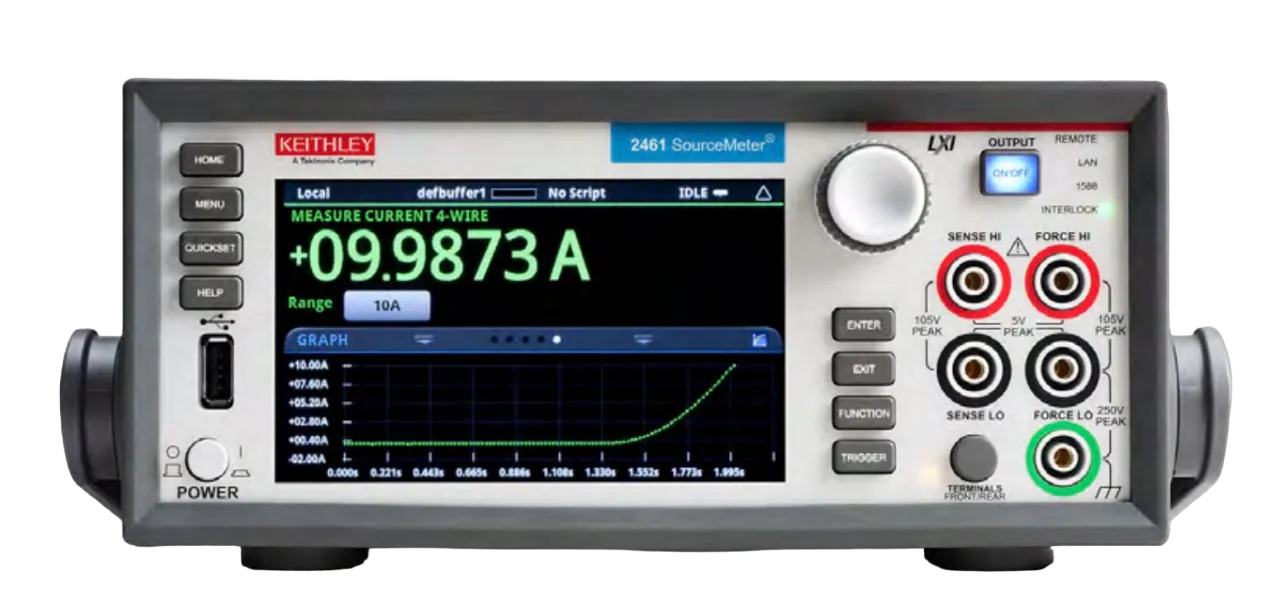

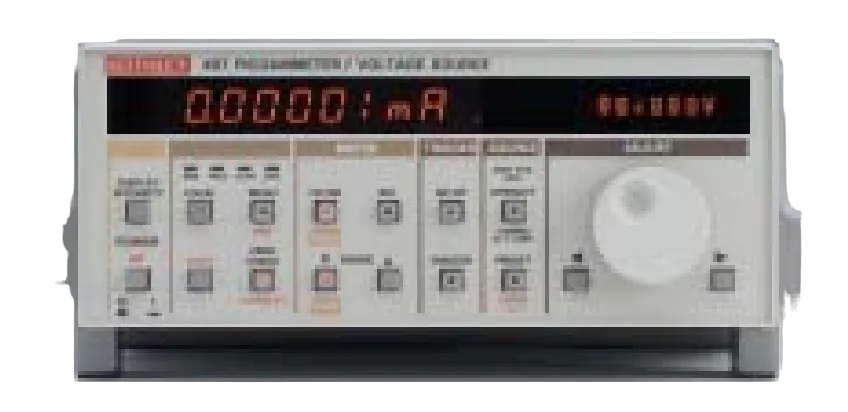

Receiver Current/Power Source Meter

Current/Power Source Meter Picoammeter

Picoammeter Other Meters

Other Meters Optical Fiber

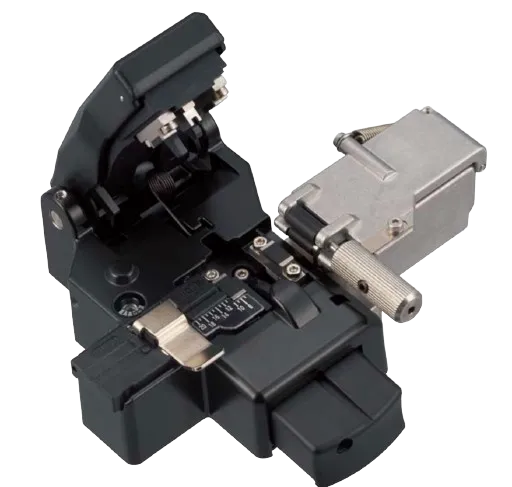

Optical Fiber Fiber Cleaver

Fiber Cleaver Fusion Splicer

Fusion Splicer Fiber Recoater

Fiber Recoater Optical Attenuator

Optical Attenuator Optical Head

Optical Head OTDR (Optical Time-Domain Reflectometer)

OTDR (Optical Time-Domain Reflectometer) Other Optical Instruments

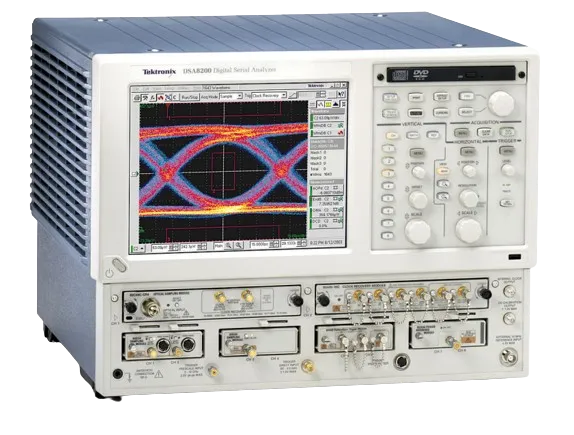

Other Optical Instruments Oscilloscopes

Oscilloscopes Curve Tracer

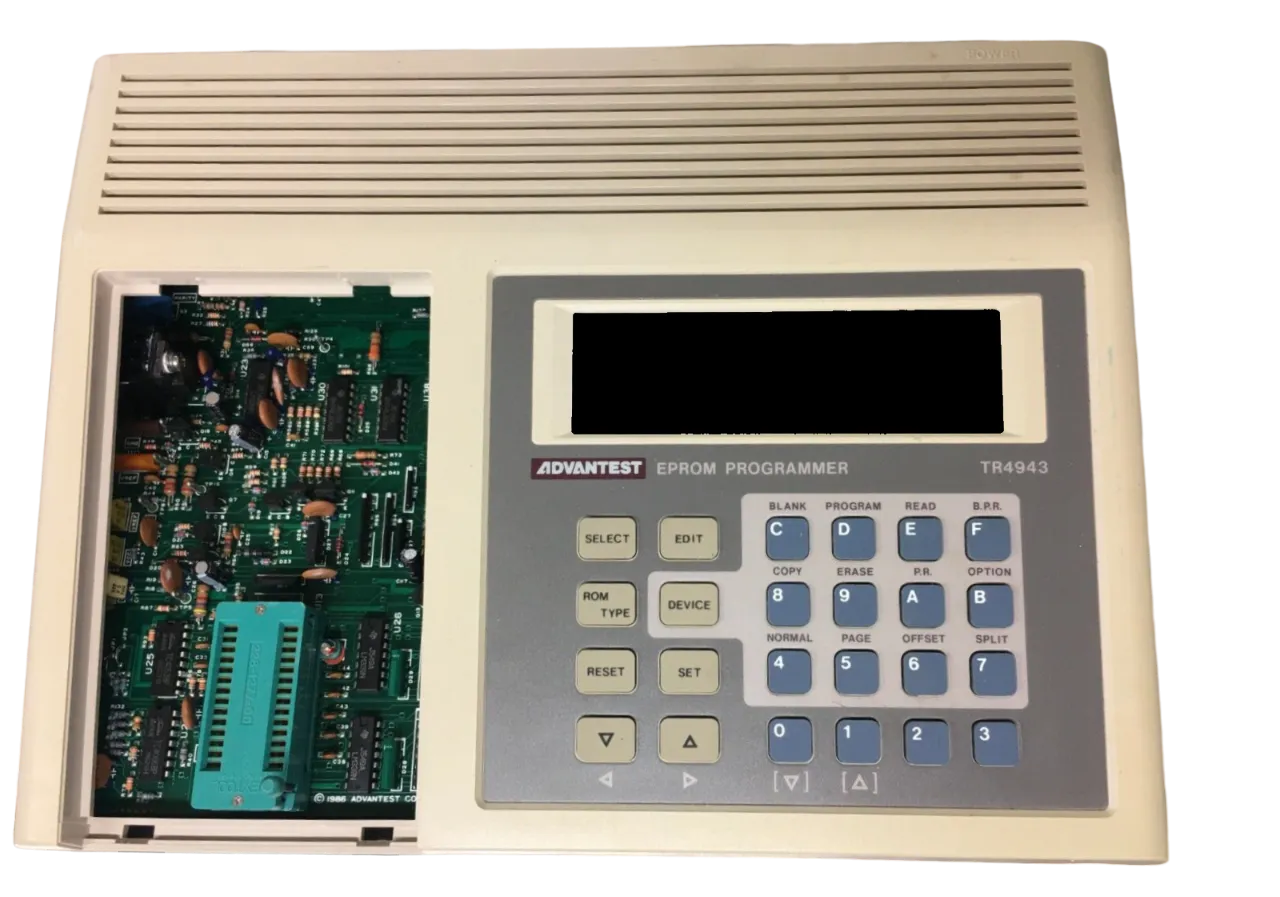

Curve Tracer EPROM Programer

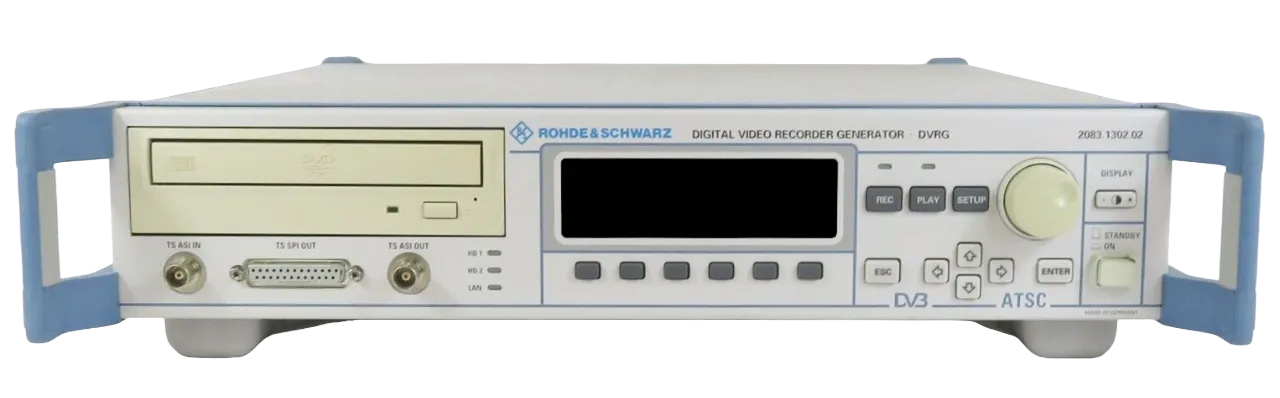

EPROM Programer Recorder

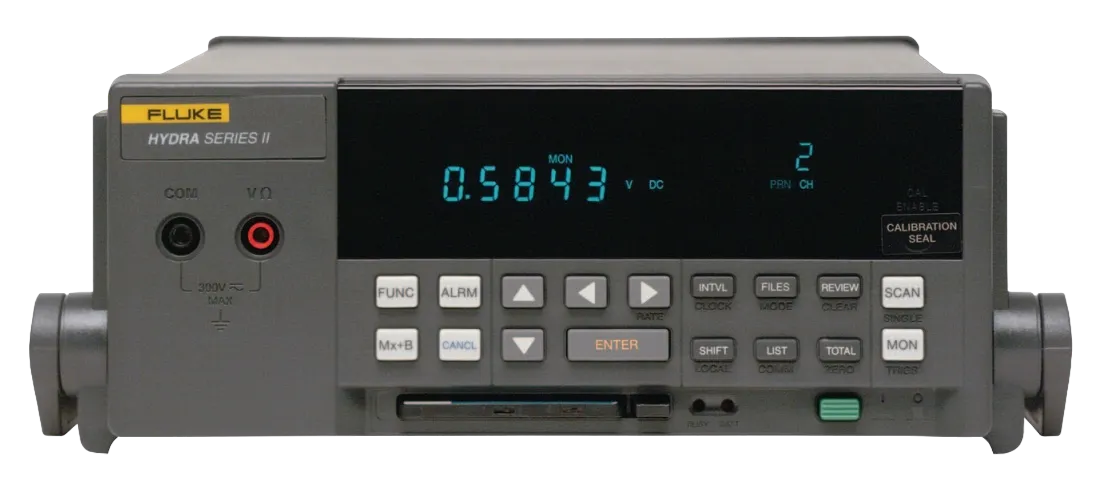

Recorder Data Acquisition System

Data Acquisition System Data Logger

Data Logger Calibration Kit

Calibration Kit Test Set

Test Set Test Chamber / Ovens

Test Chamber / Ovens Calibrator

Calibrator Controller

Controller Mainframe

Mainframe Module

Module Interfaces(GPIB, Power)

Interfaces(GPIB, Power) Switch

Switch Matrix Cards

Matrix Cards Converter

Converter Multiplexer

Multiplexer Plug-in

Plug-in Simulator

Simulator LCR Meters

LCR Meters Filters

Filters Laser Drivers

Laser Drivers Error Detectors

Error Detectors Laser Source

Laser Source Probe

Probe Power Sensor

Power Sensor Amplifier

Amplifier Attenuator

Attenuator Optical Sensor

Optical Sensor Light/LED Source

Light/LED Source Broadband / Noise Source

Broadband / Noise Source Optical / Fiber Source

Optical / Fiber Source Power Supply

Power Supply Voltage Source

Voltage Source Polisher

Polisher Microscope

Microscope Adapter

Adapter Platforms/Mounts

Platforms/Mounts Bridges

Bridges Connectors & Accessories

Connectors & Accessories View All Products >

View All Products >